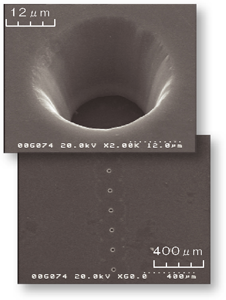

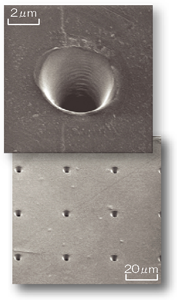

- Processing -precise hole such as 15 to 50 μm

- Processing maximum one million units of holes with maximum 100mm scale by 30 to 500 seconds.

- Positioning accuracy<±0.5μm, Diameter accuracy<±0.5μm

- No influence from changing of laser profile.

- Easy control by simple optical system.

Possible for resin processing without heat defect by UV laser.

| Sort of laser | Wave length (nm) |

Photon energy (kcal/mol) |

|---|---|---|

| CO_{2} | 10600 | 2.7 |

| YAG | 1064 | 27 |

| SHG-YAG | 532 | 54 |

| THG-YAG | 355 | 81 |

| KrF eximer laser | 248 | 114 |

| Sort of bond | Disociation energy (kcal/mol) |

|---|---|

| C-C | 80 |

| C-H | 98 |

| C=C | 145 |

| C≡C | 198 |

In case of CO_{2} laser, 50μm diameter is limit because of big limit condensing diameter by long wavelength, and melting and burnt by heat treatment.

UV laser cut directly C-C joint by high photon energy.

- Possible for processing multi holes collectively by large output excimer laser and multiple array of micro lens.

- Processing maximum one million units of holes with maximum 100mm scale by 30 to 500 seconds by beam scanning on the micro lens.

- Accuracy of hole positioning <±0.5μm, by high precise micro lens array.

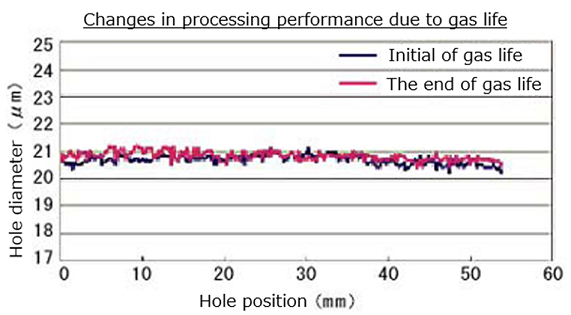

- Accuracy of hole dimension<±0.5μm, by beam vibration system.

- Equalization of beam profile without optical system and possible for high precise processing.

- Easier control than old technologies by simple optical system.

- Possible for long term stable processing without influence of excimer laser beam quality changes by beam vibration system.

Inquiries about laser business.

ENGINEERING DEPT.1

Call: +81-42-542-7100