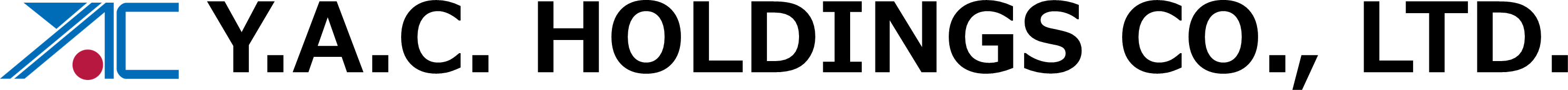

An ion beam sputtering system is an apparatus that accelerates ions extracted from plasma, collides them with a target, which is a film-forming material, blows off particles, and forms a film on a substrate on the opposite surface. The unique bucket type ion source enables film formation that features high uniformity and good reproducibility. From small to large sizes, we can handle custom-made products. It is applied to various applications such as optical films, various magnetic films, superconducting films, super mirrors, etc., and supports the manufacture of devices that are the core of IoT.

1.Adoption of a bucket type ion source

- Highly uniform film formation with a stable beam shape.

- Enables good reproducibility because the sputtering amount is proportional to the beam current.

- Highly accurate control of the film formation amount is possible by high-precision control of the beam current.

- Large Capable of handling large substrates with a large-diameter ion source.

2.Adopting an ion beam method

- Stable film formation at low pressures.

- Deposition conditions and control amount can be clarified by plasma-free film formation.

- Start-up compared to magnetron system particle generation can be suppressed due to small fluctuations in film thickness.

3. For optical film applications (high reflectivity is possible)

- Continuous multilayer film can be formed with high precision control.

- Position control of film thickness by mask operation control is possible. (The film thickness can be controlled and can be used for mirrors with various shapes)

- Films with low surface roughness are possible.

- Plasma-free sputtering in high vacuum is possible.

-

Optical films, super mirrors, superconducting films, ultra thin films, super multilayer films, magnetic films for magnetic heads, etc.

| Model | IBS-100 | IBS-200 | IBS-350 | ||||

|---|---|---|---|---|---|---|---|

| Ion source size | Φ100 | Φ200 | Φ350 | ||||

| Ion source voltage | 1500V | 1500V | 5000V | ||||

| Current density | 350mA/cm~{2} | 800mA/cm~{2} | 4000mA/cm~{2} | ||||

| Substrate holder | 2 inchs ×4 | Up to your request. | |||||

| Target | Φ150mm×2 | Up to your request. | |||||

| Ion assist | Option | ||||||

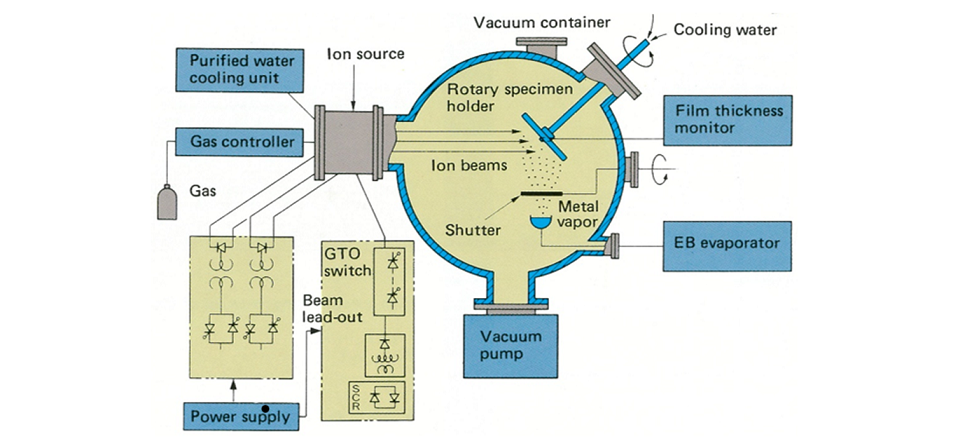

Ion beam mixing machine performs ion implantation while forming a vapor deposition film on the surface of a solid substrate, and creates a mixed layer with no boundary surface between ionic species atoms, vapor deposition metal and base material implanted in the base material. It is a machine that produces a good film. Because of its ability to generate a strong surface modification layer in a low-temperature process, it is expected to be applied in various fields such as mechatronic parts, precision molds, semiconductor tools, and engine parts.

| Items | Specifications |

|---|---|

| Ion source |

・Voltage:10~40kV(High voltage available upon request) ・ Current:1A Shrt time(Increase / decrease current upon request.) 0.4A continuous (20kV N_{2}in case of gas) ・ Beam size:Φ100mm~ |

| Vapor deposition point |

・ Electron beam heating system ・ Capacity: 5 kW (large capacity available upon request) ・ Crucible: 4 |

| Power supply point |

・ With protection device by DC switch using gate tan off thyristor. ・ With automatic restarting device. |

| Exhaust point |

Turbo molecular pump + rotary |

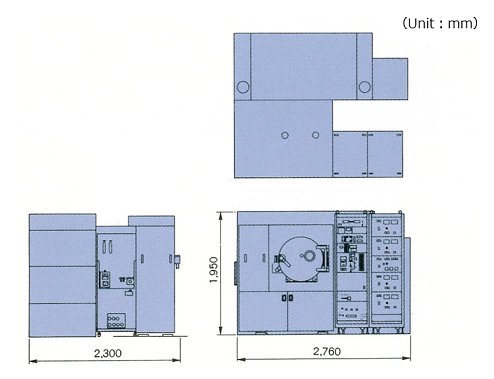

■ Dimensions

- A mixed layer is generated between the base material and the surface treatment layer, and there is no boundary between layers found in the conventional film forming method, and it is possible to generate a film with extremely good adhesion.

- Because of low-temperature processing, the base material does not undergo thermal deformation as in conventional processing, and processing in the final shape and repeated processing are possible.

- The surface treatment and film formation are non-thermal equilibrium processes, the mixing ratio of vapor deposition and ion implantation can be selected, the composition of the produced film can be controlled, and the reproducibility is excellent.

- Implanted ions have energy equivalent to hundreds of millions of degrees, so they can be applied to the production of new diamond-like materials.

- Mechatronics parts, OA parts, precision molds, semiconductor molds, semiconductor tools, precision jigs, various rolls, turbines, engine parts. semiconductor insulation cooling plates, etc.

After purchasing the machine, we will provide maintenance service for customers to use with peace of mind.

For details, please contact the following.

Inquiries about ion beam business.

ENGINEERING DEPT.2

Call: +81-294-85-6038