Ion beam etching machine is an equipment that physically make precise processing to object by letting plasma ion clash against objective material.

We have own bucket type of ion sources and possible for flat beam processing.

It is used for various type of applications such as MEMS, sensor, MRAM, power devices, high frequency devices and optical devices, and support for manufacturing of main devices of IoT.

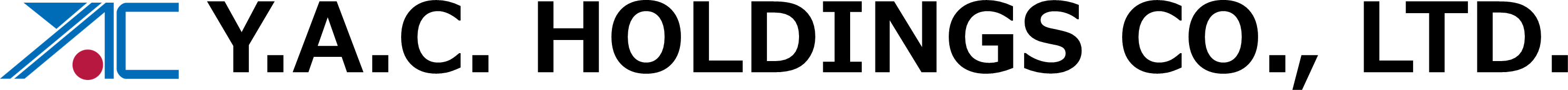

1) Ion speed and clash phenomenon

When let ion accelerate and clash against material, the following phenomenon such as accumulation, processing or pouring occur.

It is possible to process electronics devices by using those phenomena.

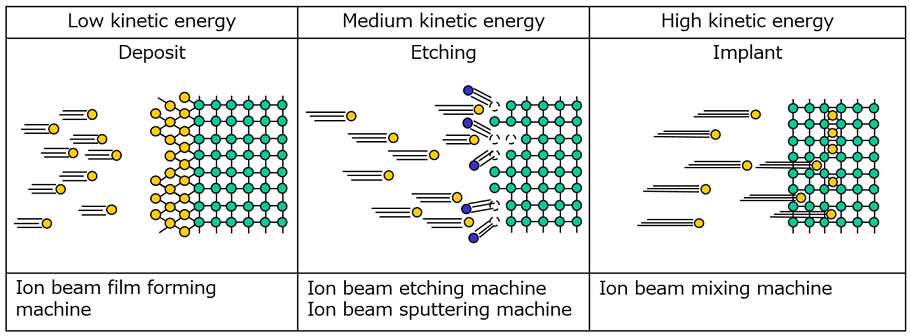

(2) Generating plasma ion

When current flows through the filament to generate thermo electrons and Ar gas flows into the ion source to generate arc discharge, Ar molecules collide violently with the thermo electrons and ionize.

In this way, Ar + ions, electrons (-), and non-ionized Ar molecules coexist and generate an electrically neutral Ar plasma as a whole.

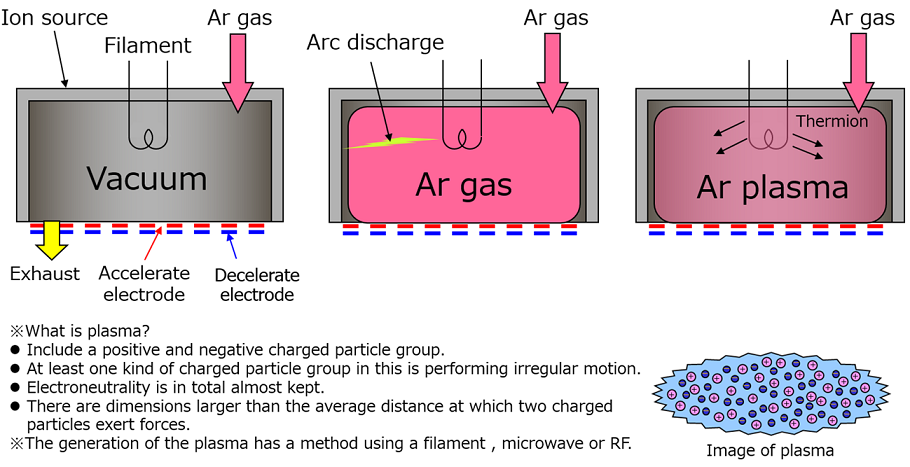

3) Beam extraction from the ion source

By applying a voltage to the accelerate electrode to give a positive potential to the electrically neutral plasma, ions leaking from the hole opened in the electrode, it will fly toward the substrate holder at 0V potential.

Etching is performed by the flying ions hitting the substrate to be processed.

Most materials can be Etched by physically hitting the ions. Therefore, it is suitable for etching multi-layer films and materials that are difficult to cut by chemical reaction.

Also, since only Ar gas, which is normally an inert gas, is used, no exhaust gas treatment equipment is required.

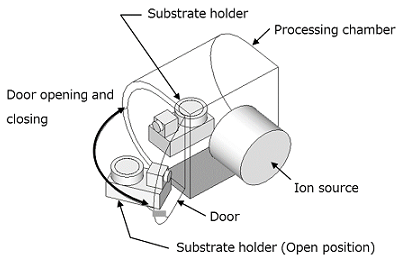

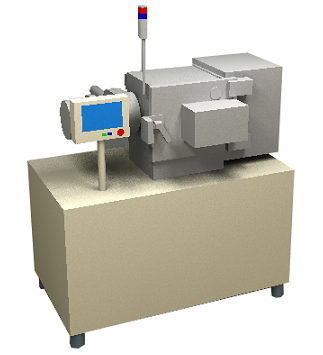

Small machine suitable for development and small lot manufacturing.

Manual mounting type

- High etching rate and low rate control possible.

- Highly uniform processing with a uniform parallel beam.

- Fine processing of difficult-to-etch materials.

- 3D workpiece can be processed.

- Rotating + tilting substrate holder.

- A variety of chuck methods can be selected.

- Compact footprint.

- Load lock.(Optional)

- End point detection system.(Optional application for load lock type)

- Electronics devices, MEMS manufacturing, microfabrication research, development, test manufacturing, and small mass production

- Ion irradiation to small solid objects

| Model | IM-150 | IM-200 | |||

|---|---|---|---|---|---|

| Ion source size | Φ150 | Φ200 | |||

| Ion source voltage | 300~1000V | ||||

| Current density | ~1mA/cm~{2} | ||||

| Applicable substrate | Φ4 inchs ×1 | Φ5 inchs ×1 | |||

| Holder movement | Rotation / Inclination | ||||

| Holder cooling system |

Water cooling / Gas cooling |

||||

| Substrate changing method | Manual | ||||

Load lock model

Model equipped with load lock chamber and transfer

rod.

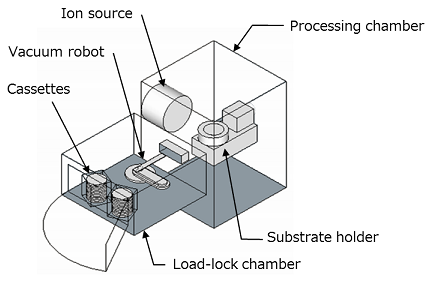

CIM Series

A model that pursues more compactness.

Machine suitable for mass production processing by cassette to cassette.

Type with automatic transfer / load lock

chamber

-

High etching rate and low rate control are possible.

-

Highly uniform processing with uniform parallel beam.

-

Micro-processing of difficult-to-process etching material.

-

Rotation + Inclined substrate holder.

-

Selectable abundant chuck system.

(Optional:Electrostatic chuck)

-

Filament-less microwave neutralizer.(Optional)

-

End point detector system.(Optional)

-

Reactive gas compatible.(Optional)

-

Filament-less RF bucket type ion source.(Optional)

- 拡大

- Filament less µwave neutralizer

(Ring plasma)

- MEMS electrode microfabrication, high-frequency filter and compound semiconductor wiring / electrode processing, magnetic head / magnetic sensor micropattern / shape processing, etc.

| Model | IML-5-1 | IML-6-1 | IML-8-1 | IML-8-2 | |||||

|---|---|---|---|---|---|---|---|---|---|

| Ion source size | Φ200 | Φ250 | Φ350 | Φ300 | |||||

| Ion source voltage | 300~1000V | ||||||||

| Current density | ~1mA/cm~{2} | ||||||||

| Applicable substrate | Φ5 inchs ×1 | Φ6inchs ×1 | Φ8 inchs ×1 |

Φ8 inchs ×2 (Two chambers model) (Selectable electrostatic chuck) |

|||||

| Holder movement |

Rotation / Inclination |

||||||||

| Holder cooling system |

Water cooling / Gas cooling |

||||||||

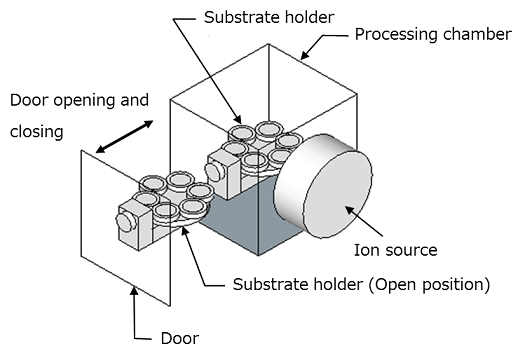

Two chambers model

Machine suitable for big size substrate and batch processing.

Manual mounting, 6 sheets simultaneous processing

model

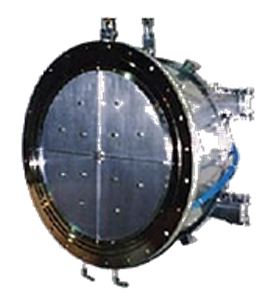

- Maximum diameter of 580 mm bucket type ion source.

- Highly uniform processing with a parallel beam.

- Fine processing of highly uniform difficult-to-etch materials.

- High uniformity and high throughput are possible.

- High etching rate and low rate can be controlled.

- Chuck method can be selected.

- Compatible with irregular substrates, square substrate., mixed irregular substrates, compatible with substrate size.

- Filament-less μ-wave neutralizer.(Optional)

- Endpoint detector system.(Optional)

- Filament-less RF bucket ion source.(Optional)

- 拡大

- Φ580 bucket type ion source.

-

Precise processing for magnetic heads, micro processing for printer heads, etc.

| Model | IM-580 | IML-580-LL | |||

|---|---|---|---|---|---|

| Ion source size | Φ580 | Φ580 | |||

| Ion source voltage | 300~1000V | ||||

| Current density | ~1mA/cm~{2} | ||||

| Applicable substrate | Φ4 inchs ×10 Φ5 inchs ×9 Φ6 inchs ×8 | Φ6 inchs ×6 | |||

| Holder movement |

Rotation / Inclination |

||||

| Holder cooling system |

Water cooling / Gas cooling |

||||

| Substrate changing method | Manual | Cassette to cassette | |||

Automatic conveyance, with load lock, 6 substrates

simultaneous processing type

1

1

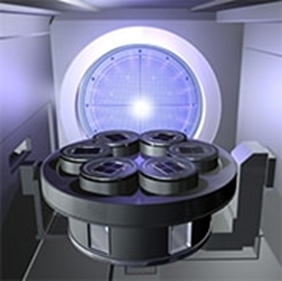

- 拡大

- Inside image of processing chamber

We offer sample processing tailored to the customer's application free of charge for the first time with various ion beam etching machines owned by us.

For details, please contact the following.

We offer contracted processing with various demonstrations of ion beam etching machines that we own.

For details, please contact the following.

After purchasing the machine, we will provide maintenance service for customers to use with peace of mind.

For details, please contact the following.

Inquiries about ion beam business.

ENGINEERING DEPT.2

Call: +81-294-85-6038